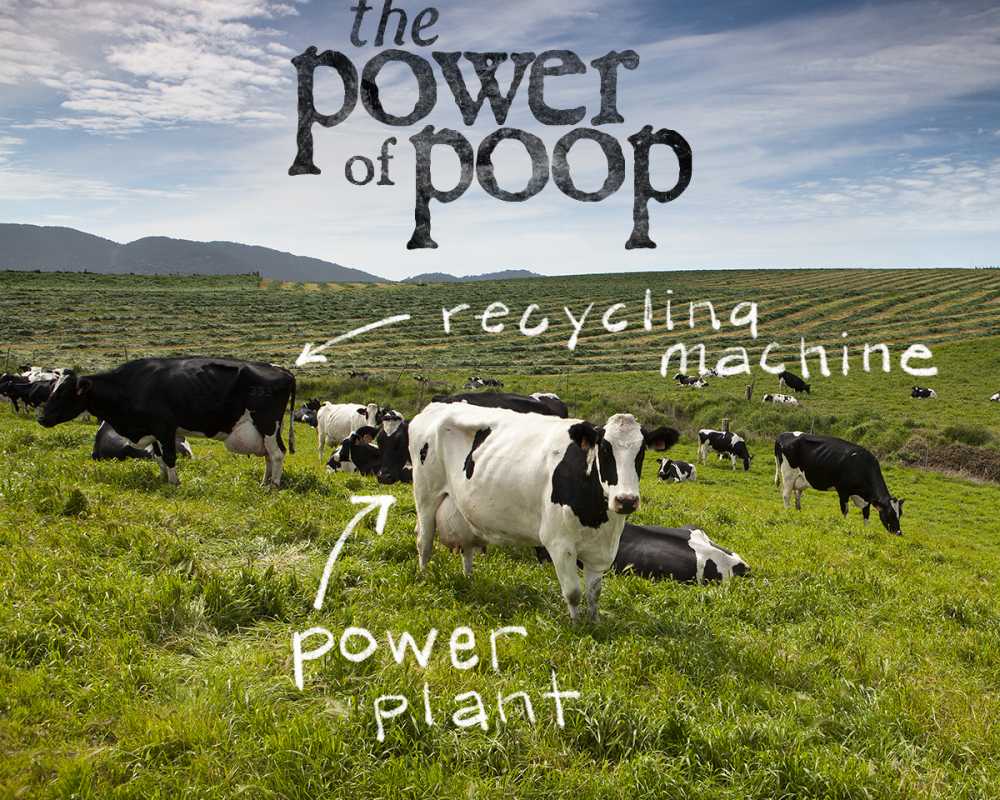

Our methane digester reduces greenhouse gas emissions and creates sustainable energy.

Yes, this is a story about cow manure, and how we’re turning it into a renewable source of energy. So, while it may sound a little gross at first, it’s actually a fascinating process and a big part of our commitment to sustainability and environmental stewardship.

The Poop Loop

Reuse, recycle and regenerate. For us, sustaining the natural environment that supports our farm is all about making sure as little as possible gets wasted. That philosophy even extends to the management of our animal waste. In 2009 we installed a bio digester... here’s how it works.

The whole process starts in the barns. Two times every day the waste is flushed from the barns using recycled water. (We’ll get to where the water comes from later.) If you’ve visited the farm, you may have noticed that the barns are on a slight incline. That allows for a gravity-flow system that moves the waste efficiently into a machine that separates solids from liquids.

Two things come from the separation process. The solid waste is composted and could have one of several uses. It could end up in bedding for the cows or fertilizer for the pastures. Some of it also goes to our friends and neighbors at the Point Reyes Compost Company in a blend they call “Bob’s Best.”

The liquid manure, which still has a fair amount of nutritional and fibrous material, goes into the holding pond covered by a big, balloon-like tarp. This is where the magic happens. In a lot of ways, what occurs under the tarp is similar to what happens inside a cow’s stomachs (yeah, they have four, but that’s another story for another blog). In this version of digestion microbes feed on the nutrition-rich waste to create methane gas. Only, instead of that gas being released into the atmosphere, it remains trapped under the big tarp. Score one for the environment.

Under the big bubble there are perforated pipes that capture the gas. This gas is cleaned by an air injection process, “scrubbing”, which causes the hydrogen sulfide to become a liquid form in the manure pond. The gas is then moved through a condensing machine that takes out as much moisture as possible. What is our sustainability benefit here? The hydrogen sulfide byproduct goes back under the tarp in liquid form where it adds to the functional operating retention time of the whole system.

The final product is clean natural gas that operates a combustion engine to produce energy to power the dairy and creamery buildings (about 65% of our total on-farm needs). It’s what you could call an environmental win/win. Less methane, a known greenhouse gas, is released into the atmosphere (because it is burned in the combustion engine), and less outside energy is required to run our milking and cheese making operations. The system even reduces the number of flies on our farm because there is less manure to attract them and no place for them to lay their eggs.

This ecological good news story doesn’t end there. Remember the water that started the whole process by flushing the waste from the barn floor? Well, it’s actually overflow from the methane digester. The new liquid comes into the system, forcing the water to overflow into a capture pond and from there it’s pumped into a flush pond where it’s reused in the barn flushing process. Here in California, every drop of water is precious, and we’re thrilled to achieve our goal of conserving as much as possible.

Our methane digester is just one part of our overall commitment to renewable energy, reuse and recycling, water conservation and low impact farming. Why do these things matter so much to us? Because we care deeply about the health of the planet and because we know that cows raised in a healthy environment produce better quality milk. In that way, our sustainability practices also translate directly into better cheese, and what could be more important than that?